BUILDERA SMARTGAUGE® MULTICOMPARATOR

ACI and ASTM Compliant

7-in-1 MULTICOMPARATOR FOR

INSPECTORS, ENGINEERS AND INSURANCE ADJUSTERS

INTRODUCTION

Buildera developed the new BUILDERA SMARTGAUGE® MULTICOMPARATOR™ for a leading engineering, consulting and inspection firm, and now offers it to contractors, engineers, inspectors, and insurance adjusters worldwide. Combining seven measurements in one, this powerful tool builds on the proven BUILDERA CRACKMON® 224R Crack-Width Comparator, and sports an extended measurement range with seven powerful measurement functions. Measure length, tile lippage, crack width, material thickness, hail-impact diameter, slope and common-nail sizes—all in a handy tool that fits inside your pocket, folio, or toolbox. For a visual user guide, scroll down to the “USER GUIDE” section below.

BUILT TOUGH FOR ALL-WEATHER USE

Crafted from heavy-duty structural-grade polycarbonate, BUILDERA SMARTGAUGE delivers daily value in a compact form. Drop it from a ladder—no problem. Drop it from a roof—it won’t break. And in the unlikely event it fails to perform, send us a picture and we’ll replace it free within 12 months from the purchase date. Enjoy the peace of mind of Buildera’s five-star customer service and no-hassle warranty. Best of all, BUILDERA proudly manufactures the SMARTGAUGE in the USA from premium materials and state-of-the-art equipment. Explore the BUILDERA SMARTGAUGE today, and discover how you and your employees can benefit from seven measurements in one.

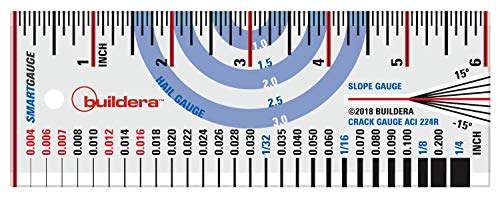

FIGURE 1. Buildera SMARTGAUGE MULTICOMPARATOR. Front side includes a color-coded ruler, hail gauge, crack-width/material-thickness gauge, and slope gauge.

MEASURE LENGTH AND LIPPAGE

A handy six-inch ruler—with user-trimmable top and bottom edges—offers precise length and differential “lippage” measurements. Graduated ruler tick marks and the thoughtful use of color improve legibility in tight spots—indoors and out.

MEASURE HAIL IMPACT DIAMETER

The integral color-coded hail gauge speeds measurements of hail-impact damage up to 3” in diameter. Due to the way it’s centered and overlapping the ruler, finer measurements are also possible by counting tick marks from the nearest 0.5” increment.

MEASURE CRACK WIDTH (ACI 224R-01) AND MATERIAL THICKNESS

Building on the CRACKMON® 224R success, the BUILDERA SMARTGAUGE includes an ACI-compliant crack-width comparator for measuring cracks as small as 0.004” up to 0.25” in 28 increments. The crack gauge with its transparent edge also doubles as a handy material-thickness gauge for common building materials such as sheet metal, wood veneers, tile and more.

MEASURE SLOPE

A transparent slope gauge between ±15º (30º total range) measures slope relative to a horizontal or vertical reference line. Typical uses include slope estimates of cracking and settling foundations, retaining walls, hardscaping and more.

FIGURE 2. Buildera SMARTGAUGE MULTICOMPARATOR. Rear side includes a common-nail gauge (ASTM F1667-18) and common-to-box nail conversion chart (Journal of Light Construction).

MEASURE NAIL SIZE AND GAUGE (ASTM F1667-18)

On the rear side of the gauge, a common-nail gauge conforming to ASTM F1667-18 simplifies field verification in 12 sizes ranging from 2d to 20d (1” to 4”). Compare both length and width to weed out inferior imports and non-conforming nails. A handy conversion table from common nails to box nails is also included. And to top it off, an integrated hole lets you hang it on a nail on the job site, on a garage peg board, or a carabiner clip on your tool belt.

INNOVATIVE DESIGN OFFERS MANY FEATURES AND BENEFITS

Multiple gauges in one save space and money.

Individually serialized for engineering traceability and inspection documentation.

Heavy-duty architectural-grade polycarbonate body withstands extreme temperatures from sub-freezing to boiling.

All graphic and numerical indicators are back-printed to eliminate parallax when viewing from the top surface.

Thick, layered UV-cured inks chemically bonded to the substrate resist scratching with repeated use. Even if the back layer were completely destroyed from excessive wear and tear, the front-view is fully protected by a full middle layer of opaque white ink.

Generous use of color in multiple layers improves legibility and measurement acuity in different lighting conditions.

QR code on back allows quick access to online documentation using a mobile phone. Most new phones (iPhone/Android) can automatically scan a QR code simply by focusing the camera on the code. Apps are available for older phones to read QR codes if yours is not suitably equipped.

BUILDERA SMARTGAUGE is custom printable with your color logo; 500 piece minimum order quantity. Contact Buildera for tiered pricing options and lead time.

USER GUIDE

OVERVIEW

The BUILDERA SMARTGAUGE® MULTICOMPARATOR consists of two measuring sides—in inches (or decimal/fractional inches)—and is intended for the US market. Contact Buildera for metric/international version pricing and availability.

The front side includes four separate gauges:

6” ruler in 1/16” graduated increments;

Crack-width and material-thickness gauge (ACI 224R-01), which may be used to measure very-fine to medium cracks, as well as edge thickness of common building materials, including but not limited to sheet metal, plastics, glass, laminates, tile and wood veneers;

Slope gauge (±15º in 5º increments), and;

Hail gauge (0.5” to 3.0” diameter in 0.5” increments).

The rear (back) side includes:

A common-nail gauge (ASTM F1667-18) to quickly compare common nails for conformance to ASTM F1667 size and width/wire gauge, and;

Common-nail to box-nail conversion chart.

MEASUREMENT EXAMPLES

FIGURE 3. To measure cracks or materials up to 1/4” wide, place the transparent edge of the crack gauge over the crack and visually align the gauge until the graduated line width matches the crack width. If the crack width falls in between two values, visually interpolate for improved accuracy. When using as a material thickness gauge, place the gauge over the edge of the material to approximate its thickness without requiring a calipers. Crack widths in red correspond to key ACI 224R-01 limits for varying conditions. Figures in blue are in fractions, and represent common material thicknesses from 1/32” to 1/4”.

FIGURE 4. In this example, a very fine crack measures 0.012” wide, which is a key value limit in ACI 224R-01.

FIGURE 5. For cracks or other measurement requirements greater than 1/4”, use the included ruler with the long red and black reference line as the zero point. For precise lippage or inside corner measurements, users may trim the top edge using a belt sander or disk sander, being careful to maintain a square and perpendicular edge up to the thin black line.

FIGURE 6. Use the slope gauge to measure angular offsets from a vertical or horizontal reference. The bright red line is the baseline. Measure from 0º to ±15º in 5º increments, for a total of 30-degree range. If the slope exceeds ±15º, simply rotate the gauge to use the +15º or -15º indicator as the baseline. This effectively doubles the available range.

FIGURE 7. Quickly measure hail-impact diameter of metal roofs, corrugated panels, vehicles and other surfaces using the colored hail gauge. If the impact zone exceeds 3” in diameter, use the ruler to extend the measurement up to 6” (that would be grapefruit-sized hail!).

FIGURE 8. The back side includes a common-nail gauge comparator conforming to ASTM F1667-18 standard for driven fasteners. Simply overlay the nail from the black reference line and compare the length and width. A conversion chart between common and box nails is included for Spruce-Pine-Fir lumber. Always check with your latest building codes as rules may vary by city and state. If the top edge is sanded for lippage measurements, then hang the nail head over the top edge for precise length measurements. Fasteners that do not meet the specified length and width may be substandard and dangerous. Always verify your source and ensure that driven fasteners meet ASTM F1667-18 standards.

REFERENCE LINE AND LIPPAGE MEASUREMENTS

The horizontal red and black reference line extending across the front of the gauge top forms the zero reference line for the ruler scale, and is marked precisely by the black line at its center. The red color enhances measurement visibility and differentiates the major tick marks from the intermediate minor tick marks. For most common measurements, except lippage, no modification to the BUILDERA SMARTGAUGE is needed.

In some applications—such as in tile setting or inspection where adjacent tiles are uneven—users may compare the differences in elevation between edges of adjacent tile modules (also called lippage) for conformance to codes, and to avoid accidental tripping hazards. ANSI (American National Standards Institute) standard A108.02-2017 defines the allowable lippage tolerance depending on the tile size and grout width. In most cases, allowable lippage ranges from 1/16” to 5/16” inch. However, for very small, thin tiles and stone with grout lines less than 1/4”, lippage may be as small as 1/32”.

To prepare the BUILDERA SMARTGAUGE for precise lippage measurements, the user may use an orbital sander, belt sander, or disk sander to carefully trim the top edge just up to the fine black line along the top edge of the gauge (contained within the first edge-to-edge red line). This DIY modification can provide extreme accuracy of subsequent measurements well beyond typical manufacturing and printing tolerances or what a tape measure can provide. Buildera designed the SMARTGAUGE specifically to allow user-trimming of approximately 1/32” to 1/16” material along the top and bottom edges where such edges are necessary zero reference points.

BUILDERA SMARTGAUGE® PRODUCT SPECIFICATIONS

UPC | EAN

816291010655 | 0816291010655

Item quantity (1 EA)

Custom versions available with logo—contact Buildera

MSRP (US LIST PRICE)

$29.95/EA plus free shipping in the US

Contact BUILDERA for volume pricing and custom logo options

MEASUREMENT FUNCTIONS AND CONVERSIONS

Ruler (0” to 6” in 1/16” increments)

Lippage (1/32” min, 1/16” to 5/16” typical range) - requires user modification

Hail gauge (0.5” to 3.0” in 0.5” increments)

Crack-width gauge (0.004” to 0.250”), ACI 224R-01

Material thickness (0.004” to 0.250”) - use crack-width gauge

Slope gauge (±15º in 5º increments)

Nail gauge (2d to 20d), ASTM F1667-18

Conversion chart (common to box nails)

PRINTING

Multilayer UV-cured heavy-duty ink with white middle layer for improved contrast, legibility and durability

OPERATING TEMPERATURE RANGE

-40 ºF to 212 ºF (-40 ºC to +100 ºC)

COEFFICIENT OF LINEAR THERMAL EXPANSION

38 ppm/ºF (68 ppm/ºC), ASTM D696

TENSILE STRENGTH AT YIELD

9,300 PSI, ASTM D638

FLEXURAL STRENGTH

13,450 PSI, ASTM D790

ROCKWELL HARDNESS

70 (M-scale), ASTM D785

IMPACT RESISTANCE

18 ft.lbs/in, Izod notched @ 0.125”, ASTM D256

FLAMMABILITY (SUBSTRATE)

HB (horizontal) to V-0 (vertical), UL-94

MATERIAL (BODY)

3/16” (4.5 mm) structural-grade extruded polycarbonate

SIZE

6.13” (156 mm) tall x 2.25” (57 mm) wide

NET WEIGHT (GAUGE ONLY WITHOUT PACKAGING)

1.6 oz (45 g)

COUNTRY OF ORIGIN

Engineered and made in USA

Patents pending

MAINTENANCE

The BUILDERA SMARTGAUGE Multicomparator is virtually maintenance-free. Periodic cleaning with ordinary detergent and water are all that’s necessary. Wipe dry with a soft micro-fiber rag. Avoid using solvents or other harsh chemicals, which could damage the surface or ink. Very fine plastic polishing compounds or light-duty automotive scratch removers may be used on the top surface to buff out minor surface scratches from ordinary use. Always test a small area first before proceeding. Do not use abrasive cleaners, which may damage the polished finish.

MANUFACTURER WARRANTY

BUILDERA warrants every SMARTGAUGE multi comparator for 12 months from date of purchase against manufacturing defects or breakage. Normal wear and tear is excluded. Minor surface scratches may occur during use and do not affect accuracy or usability. See maintenance recommendations above.

REFERENCES

American National Specifications For The Installation Of Ceramic Tile - Version 2017.3

K. Simpson. “Warpage, Lippage and Related Challenges (NTCA),” TileMagOnline.com (NTCA), October 2007

SMARTGAUGE® and SMARTGAUGE® MULTICOMPARATOR™ are trademarks of BUILDERA.