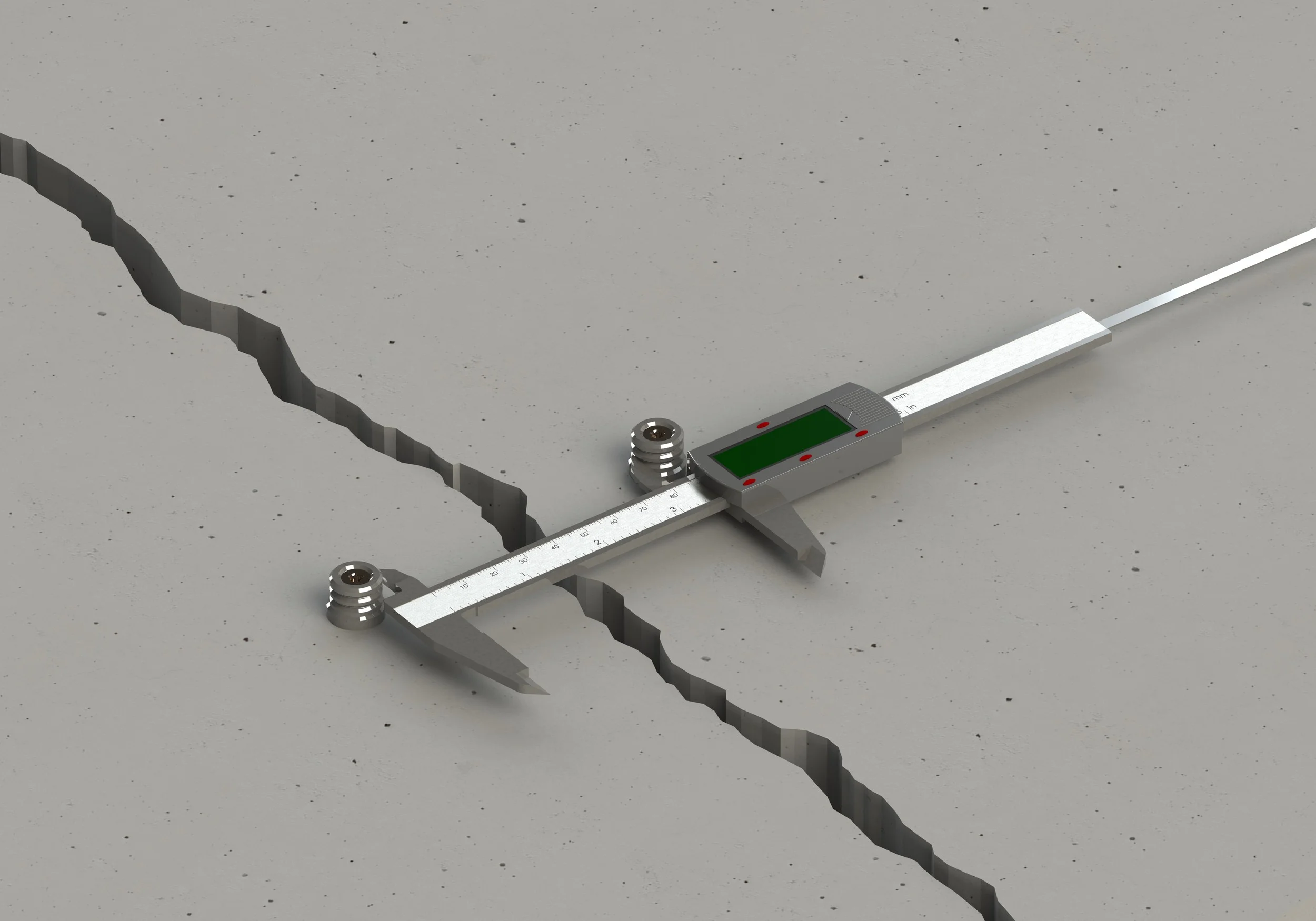

CRACKMON® CRACKPOINT™ 90ti Caliper CRACK Marks for Industrial Crack Monitoring

Download Data Sheet

Click PDF Icon to download full data sheet and installation instructions.

Literature Number

CM-DS-90200-00050EN

Version

1.2

Last Revision Date

February 10, 2016

Product Information

Features and Benefits

- Measure cracks to .001” with precision calipers such as Mitutoyo®, Starrett®, and Fowler®

- Patent-pending caliper-channel design ensures consistent measurement every time

- Corrosion-resistant titanium construction endures marine and industrial use

- Buildera TamperLok™ tamper-resistant design features fastener and captive epoxy chamber

- Engineered and made in the USA

Civil, Geotechnical & Structural Forensics

- Airports, bridges, dams, highways, hydroelectric plants

- Commercial and residential buildings, historic monuments

- Foundations, basements, seismic retrofits, preservation

- Industrial plants, petroleum rigs, ships

- Power grid, transmission towers, nuclear reactors

Product Description

Specify CRACKMON® CrackPoint™ TR50ti Caliper Marks for all indoor, outdoor, and corrosive environments where high reliability and vandal resistance are desirable.

Buildera manufactures the CRACKMON® CrackPoint™ TR50ti from commercially-pure titanium to aid measurements of structural cracks to within ± 0.001” (± 0.025mm) typical resolution. The exclusive caliper- groove design confidently interlocks with user-supplied analog or digital calipers to improve measurement accuracy and consistency. Ideal for saltwater and harsh industrial outdoor use, all-titanium construction offers superior corrosion resistance—even when compared to type 316L stainless steel.

Mount with tamper-resistant stainless steel screws (supplied) and optional structural adhesive. Available in single-groove (TR50ti-A) and dual-groove (TR50ti-B) versions. Starter kit includes (1) TR50ti-A, (1) TR50ti-B, (2) anchors and (2) security fasteners.

Buy on Amazon

Ordering Information

CRACKMON® CrackPoint™ TR50ti Kits (Retail)

Model TR50ti-Kit-1 (1 pair including fasteners)

816291010334 (UPC)

Model TR50ti-Kit-10 (10 pairs including fasteners)

816291010341 (UPC)

Model TR50ti-Kit-50 (50 pairs including fasteners)

81629101058 (UPC)

Each CRACKMON® CRACKPOINT™ Kit includes:

- Stated quantity of CRACKPOINT pairs

- Each pair includes (1) TR50ti-A (single groove) and (1) TR50ti-B (dual groove).

- Alligator® A6 Anchors (1/4" hole required)

- #8 x 1.5” flat-head TorxPlus® tamper-resistant stainless-steel screws (18-8 alloy)

- Printed installation instructions

- Epoxy and calipers sold separately

Bulk/Resale (50 Minimum Order Quantity per UPC)

CRACKMON® CRACKPOINT™ TR50ti-A Caliper Marks (1 Caliper Groove)

816291010266 (UPC)

CRACKMON® CRACKPOINT™ TR50ti-B Caliper Marks (2 Caliper Grooves)

816291010273 (UPC)

CRACKMON® CRACKPOINT™ TR50ti-HW-10 Tamper-Resistant Mounting Hardware

816291010280 (UPC)

Model TR50ti-IPR20 Security TorxPlus® Bit

816291010297 (UPC)

Related Products

CRACKMON® 4020A Kit (3-Qty)

816291010006 (UPC)

CRACKMON® 224R Crack Comparator

816291010112 (UPC)

STRUPOXY™ Thixotropic Epoxy Adhesive

816291010099 (UPC)

CRACKMON® TRACARD® 3D StarterPak (12)

816291010068 (UPC)

CRACKMON® TRACARD® 3D Refills (50)

816291010082 (UPC)

Engineering Specifications

Dimensions (Dia x H)

0.62” x 0.50” (16 x 13 mm)

Crack Width Range

0-12” caliper-dependent

Resolution

± 0.001” (± 0.025mm)

Repeatability

± 0.002” (± 0.050mm)

Grooves

1 (model TR50ti-1), 2 (model TR50ti-2)

Material

Titanium

UNS

R50400 (Grade 2 Commercially Pure). Certificate of origin available.

Country of Manufacture

USA (Patent Pending)

Standard Finish

Natural titanium oxide (silver-gray)

Optional Color Finish (100 piece order min)

Potentiometric anodizing: light yellow, bronze, purple, dark blue, light blue

Fastener Mount (recommended method)

#8 x 1.5” Tamper-Resistant TorxPlus® flat head sheet-metal screw, 18-8 stainless-steel alloy, corrosion-resistant. When using security TorxPlus® fasteners, an IPR20 driver bit is required.

Epoxy Mount

Proprietary TamperLok™ adhesive well (patent pending)